Unit 4: Lean Thinking Applied to Field Production, Last Planner System®

In Unit 4 we examine the Last Planner System®, LPS, for the construction phase of project delivery and how it applies the six tenets of Lean Construction.

- Lesson 1 - Introduction to Last Planner System® (LPS)

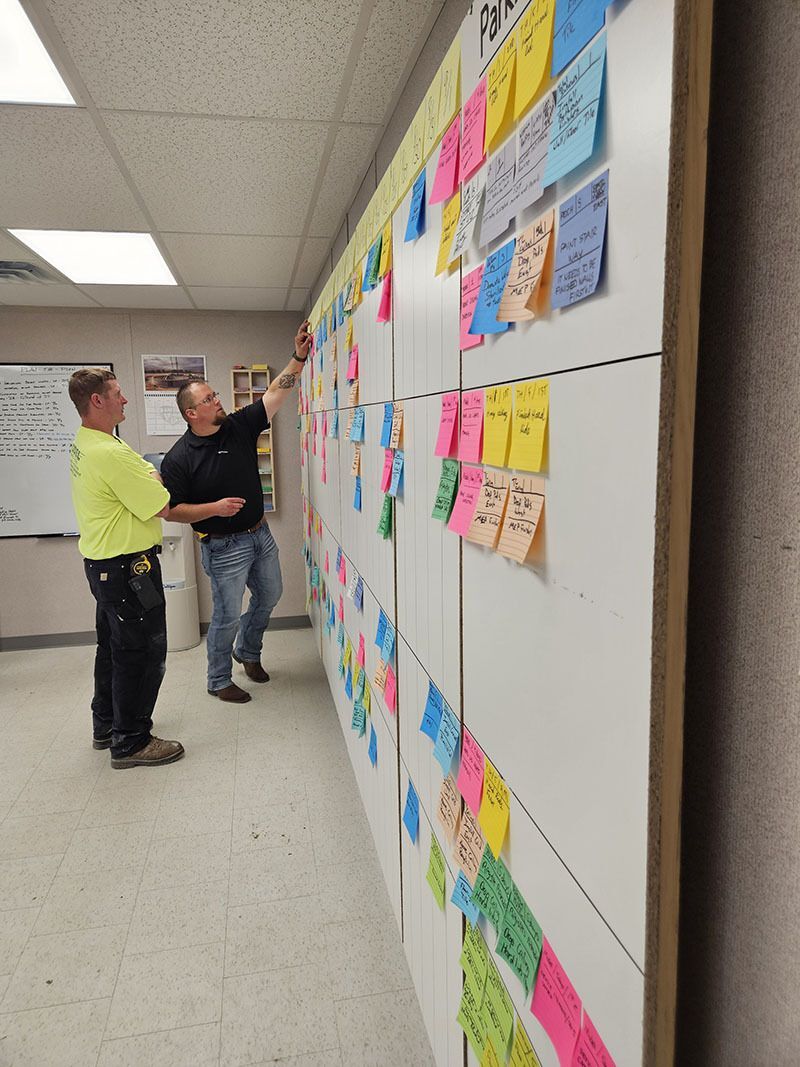

Describes how the LPS is a method of planning and control for the entire project. LPS is a common starting point for companies or projects embarking on a Lean journey. This lesson introduces LPS in terms of how it embodies the six tenets both in its design and goals in the context of field production.- Lesson 2 - Details of the Last Planner System

Describes the ideal for running the full LPS. Participants will learn the different tools, visuals, and formats that are used, but their goal of each conversation is the same. This lesson shows the steps of the Last Planner System and how it gets more detailed the closer teams get to the work. As the lesson progresses participants see the purpose of each level of the LPS, and how the levels of the LPS work together. Participants will identify methods to encourage trade partner participation in each level of the LPS, and measure to see if processes are being followed and achieving the desired results.